Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Formation and Standardization of Gluten Free Cookies made from Buckwheat (Fogopytrum Esculentum) Flour

Authors: Monika Vijay Chunchawar, Jayanand Morey , Sana Israil Sheikh, Chaitanya Awale, Ajay Durge, Prashant Watkar, Lilesh Pustode

DOI Link: https://doi.org/10.22214/ijraset.2024.62220

Certificate: View Certificate

Abstract

The consumer demand is increasing for composite flour base bakery products like cookies and biscuits. The incorporation of buckwheat flour into rice, corn, flour can prove to be essential in composite flour base cookies. It has beneficial nutraceutical properties and its gluten- free nature can play important role in preventing celiac problem. The physicochemical properties of buckwheat flour and rice, corn, flour, were studied and cookies were prepared with the incorporation of buckwheat flour in 100, 50, 75 % concentration with other flour to measure the quality and acceptability of cookies. As the concentration of buckwheat flour was increased, spread ratio of cookies decreased. With the increase in the level of buckwheat flour in the formulation, the sensory scores for texture, appearance, flavor of cookies decreased. The score of flavors reduced significantly to 5.71 at higher concentration, possibly due to presence of flavonoids compound (Rutin) having bitter taste on buckwheat flour. The cookies formed with addition of 75% buckwheat and 100% Wheat got high overall acceptability score respectively. The present study was conducted to the development of buckwheat cookies supplemented with wheat flour. Dehulling and milling of common buckwheat was conducted to obtain flour. Obtained buckwheat and wheat flour were examined for their proximate compositions. Buckwheat flour contained 11.6% moisture, 15.79% crude protein, 1.81% crude fat, 1.83% ash, 0.70% crude fiber content 68.27% N.F.E while wheat flour found having moisture content 13.12%, crude fiber content 1.93%, crude fat 1.42%, crude protein content 12.53%, ash content 1.57% and 69.43% N.F.E respectively. Wheat flour at 10, 20, 30, 40 and 50% ratio, was incorporated with buckwheat flour to make composite flour and the developed cookies were analyzed for proximate analyze. Supplementation of wheat flour significantly influenced the proximate of buckwheat flour bas cookies. Moisture contents, crude fiber contents and N.F.E (Nitrogen Free Extract) increased whereas crude fat contents, crude protein contents and ash content decreased.

Introduction

I. INTRODUCTION

Celiac disease is well-known as an autoimmune system disorder and inflammatory disease triggered by gluten in the upper small intestine (Green & Cellier, 2007; Shan et al., 2002). Symptoms of individuals suffered with celiac disease include malnutrition, diarrhea, growth retardation, anemia, and fatigue (Green & Jabri, 2003). Prevalence of celiac disease has been reported to be approximately 1% worldwide and is still increasing overtime partially attributed to more clinical tests and improved diagnosis capability, primarily in Australia, Europe, and North America Common cereals containing gluten include mainly wheat, rye, and barley. Thus, there products shall not be contained in diets for celiac disease patients. Products with oat have also be concern for some people with intolerance to gluten, because contamination of oats with wheat, rye or barley can occur during grain harvesting, transport, storage and processing. The U.S. Food and Drug Administration defines gluten-free food as the food that is either completely gluten-free or does not contain any of these ingredients:

- Gluten-containing grain (e.g., wheat); 2) derived from gluten-containing

- Grain that has not been processed to remove gluten (e.g., wheat flour); and

- Derived from a gluten containing grain that has been processed to remove gluten (e.g., wheat starch), if any use of these ingredients contains the presence of 20 ppm or more gluten in food. In other words, gluten-free foods should not contain gluten, or the presence of gluten should be lower than 20 ppm. (McCabe, 2010).

Common buckwheat (Fagopyrum esculentum Moench) is a highly nutritious pseudo- cereal that is a dietary source of protein with favorable amino acid composition, vitamins, starch, dietary fiber, essential minerals, and trace elements (Filipcev et al., 2011). One of the possible ways to promote the use of buckwheat could be its utilization in formulations for snack products such as biscuits and cookies (Sedej et al., 2011). The development of a gluten network in this type of bakery product is minimal and undesirable (except for hard sweet or semi-sweet biscuits/cookies which characterized by a more developed gluten network due to the low levels of fat and sugar relative to the flour). Furthermore, the texture of these products are primarily attributable to starch gelatinization and supercooled sugar rather than a protein/starch structure (Gallagher et al., 2004). Therefore, buckwheat could be a good raw material for gluten-free cookies. Gluten-free flours could be supplemented with enzymes to promote protein networks and improve their baking characteristics. Among the enzymes used in the food industry, transglutaminase (TG) has been successfully applied in several food systems (Kuraishi et al., 2001).

Baking Industry considered as one of the major segments of food processing in India. Baked products are gaining popularity because of their availability, ready to eat convenience and reasonably good shelf life. The word cookie is defined as a “small cake” and that is what a cookie is. In fact, some cookies are made from cake batter. Some products, such as certain kind of brownies, are difficult to classify as cakes or cookies. Most cookie formulas, however, call for less liquid than cake formulas do. cookies doughs range from soft to very stiff, unlike the thinner batters used for cakes.

This difference in content means some difference in mixing method, although the basis procedure is much like those for cakes. Cookies are produced by using soft wheat flour that has relatively weak gluten strength (e.g., pastry, a blend of soft red and soft white wheat). The cookies have high fat and sugar contents and low moisture content. Mixing weak gluten in two or even three stages can help in achieving minimal gluten development, usually desired property of cookie dough. The weak gluten and the relatively high quantities of fat and sugar in the dough allow plasticity and cohesiveness without the formation of a strong gluten network. In general, cookies are formulated with high levels of sugar and vegetable shortening, or butter, and low level of water. Cookies come in an infinity variety of shape, size, flavors and textures (Laiet al., 2006).

Cookies are important baked products that are considered to be the most desirable products for all ages due to their low manufacturing cost, long shelf-life, convenience, and good eating quality. Also, cookies could be used as a vehicle to deliver essential nutrients to CD patients who require an increase in their daily recommendation of nutrients due to intestinal damage. Celiac disease (CD) is a lifelong autoimmune disorder in which the immune system of celiac patients reacts with gluten, i.e. The prolamin proteins of wheat, rye, and barley. The classical symptoms of the disease are abdominal distension, anorexia, chronic or recurrent diarrhea, failure to thrive or weight loss, vomiting, muscle wasting, celiac crisis (rare), and fatigue. The effective treatment for CD is a strict adherence to a gluten-free diet throughout the patient’s lifetime. The replacement of gluten presents the main technical problem, as it is the structure-forming protein, which is essential for formulating high-quality cereal-based products. Foods allowed a gluten-free diet includes rice, corn, soy, pea, millet, potato, sorghum, amaranth, quinoa, and buckwheat flours and by-products from those raw material. Buckwheat is suitable for celiac patients as its prolamins do not exert immunological responses like those in cereals. (Gulcin Altindag et al.2011

II. HISTORY

Cookies continued with their journey to America during English and Dutch settlement in the 1600s. Throughout the 19th century, most cookies were baked at home as special treats because of the high cost of sugar. Many early cookbooks included recipes for macaroons, jumbles, and gingerbread. Recipes for cookies in a variety of styles and flavors increased in the early1900s and continues today. Ninety percent of home bakers bake cookies, making them the most common home baked good. Half of all home bake cookies are chocolate chip. The official state cookie of both Massachusetts and Pennsylvania is the chocolate chip cookie that was invented by Ruth Graves Wakefield in 1930 at the Toll House Inn Restaurant in Massachusetts. Mrs. Wakefield sold the recipe to Nestle, who began manufacturing chocolate chips in 1939.

According to culinary historians, cookies evolved from test cakes used to test oven temperature. Small amounts of cake batter were dropped onto pans to test the temperature of the oven before the cakes were baked. Cookies are believed to date back to 7th century Persia (one of the first countries to cultivate sugar) and spread throughout Europe as a result of the Muslim conquest of Spain. By the 14th century, cookies were common throughout all of Europe. By the 1800s, cookie recipes were being published in cookbooks as 'small cakes.' In fact, the term 'cookie' comes from the Dutch word koekje or koekie which means little cake! What we call' cookies' in the United States are called biscuits in the United Kingdom and Australia, galletas in Spain, kels in Germany, and biscotti or amaretti in Italy.

III. MATERIAL AND METHOD

The present research work was carried out in lab department of food technology in Ballarpur institute of technology, Bamni. The various materials and methods used for research work are given below.

A. Ingredients

The raw materials required for the preparation of Cookies i.e., Buckwheat flour, Rice flour, Corn flour, Skim milk powder, Butter, sugar, Salt, Sodium Bicarbonate, Ammonium Bicarbonate, Almond, Flavor colors these ingredients were procured from local commercial market.

B. Instruments

The equipment and instruments used for optimization, preparation, raw material, and physicochemical analysis of biscuits were Planetary mixer, baking tray oven, Moisture analyzer Protein Analyzer Fiber Analyzer, Soxhlet Apparatus, Muffle furnace, weighing balance and other various baking instruments were available in laboratory.

C. Treatment of Combination

- Flour Particle Size Distribution: Particle size distribution of buckwheat, corn, and rice flours was determined according to the method of milling.

- Physiochemical Analysis of Flour and Cookies: The moisture, Ash, crude fiber and protein content of flour and cookies were determined by our lab. Lipids content of flour and cookies were determined using Soxhlet extraction.

IV. PREPARATION OF COOKIE DOUGH AND BAKING PARAMETERS: DIFFERENT FORMULATIONS OF COOKIES WERE OBTAINED

A. Determination of Moisture

The moisture content of Cookies was determined according to method given in (Ranganna,1995 a). 5g of crushed sample was taken in tarred crucible and dried in a hot air oven at 100 ± 5 ºC till to a constant weight. The moisture content was calculated by the formula given below.

% Moisture =Initial weight – Final weight

Total weight of sample

The most reliable and less time-consuming method for moisture determination was IR method. 3.5g to 5g of crushed sample was taken in the aluminum tray and placed the tray inside the instrument and pressed the start button and IR radiations starts and red light goes on till the complete moisture content found out, thereafter 30-40 minutes their adding’s was on the screen and blue light glows, at that time we consider the final moisture content of the sample is same as that on the screen.

B. Determination of Fat

The crude oil content was determined by the ether extraction using Soxhlet’s apparatus, according to method given in (Ranganna,1995 b).

Reagent- Petroleum ether was used as reagent and having boiling point of40-60°C.

% Crude Fat = Final Weight of Flask – Empty Weight of Flask × 100

C. Determination of Ash

The ash content was determined as a total inorganic matter by incineration of the samples at 600ºC according to method given in (Berwal et al., 2006). Remaining inorganic materials are reduced to their most stable form, oxides or sulphates and are considered as “ash”.

% Ash = Weight of Crucible with Ash – Weight of Empty Crucible Total Weight of Sample ×100

Weight of Sample

D. Determination of Protein

The protein content was determined by using Pelican Karl plus instruments; it works on the basis of Micro- Kjeldahl's apparatus, according to method given in (Ranganna,1995c).

Reagents

- Sulfuric acid

- Boric acid (4%)

- Sodium hydroxide (0%) 4. Bromocresol green indicator

- Methyl red indicator

- Catalyst mixture 10:1 (potassium sulphate 10 g, copper sulphate 1g).

- Standard Sulfuric acid (Dilute 2.7 ml conc. H2SO4 to 100 ml with Distilled water).

% Protein = (Blank value – Titrate value) × 1.401× 6.25 × 20 × Normality of NaOH

Table 9: Composition of mixture of three different flour at different levels.

|

Sr. No |

Buckwheat flour |

Corn flour |

Rice flour |

|

1. |

50% |

25% |

25% |

|

2. |

50% |

50% |

- |

|

3. |

50% |

- |

50% |

Total Weight of Sample

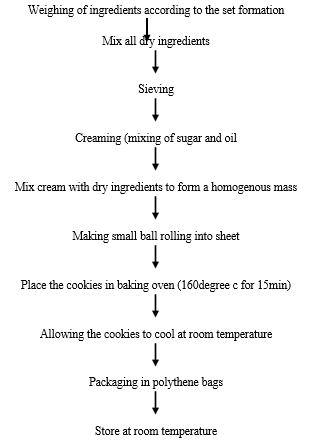

V. PROCESS FLOW OF COOKIES MAKING

VI. EXPLANATION

- Take the all-necessary ingredient as required for making the gluten free cookies. Weight all ingredients at proper amount or a proper quantity.

- The ingredient which we are taken in a proper amount, the dry ingredients are mixed.

- The dry ingredients then sieving takes place, in sieving all the waste material are removed fine dry powder we get from dry ingredients.

- Dry powder put in a vessel and add creaming (the mixture of sugar and oil). The cream must be sweet in taste.

- Then we need to mix cream with dry ingredients to form a homogenous mass. Stir it 5-10min continuously for fluffiness in the batter. Then the cookies become crunchier in taste.

- The batter of cookies is ready to roll, make the small ball rolling into sheet. Make the proper shape of cookies no cracks must be found in the cookies.

- Firstly, the butter paper is kept and butter is greased on it, then the cookies are kept and place them in a baking oven at a temperature for 160'c for 15min.

- After 15min take out the cookies from the baking oven and the cool the cookies at a room temperature.

- The cookies then packed in a polythene bag and the shelf life of the cookies is increased in the proper packing material.

10. Then the cookies are stored at a room temperature.

VIII. DETERMINATION

- Moisture Content: The standard moisture content for the cookies is below 5%. The moisture content obtained for the gluten free Cookies made from buckwheat flour were 3.57.

- Total Ash Content: The standard total ash for cookies is 1% maximum. The total ash for the gluten free Cookies made from buckwheat flour obtained were 0.91.

- Fat Content: The total fat obtained were 9.69. The standard fat percentage of cookies ranges between 20-70%. As in this study, the fat was added in wheat jaggery cookies was less. So, the fat content obtained for Cookies made from buckwheat flour ranges between 7 to 10%.

- Protein Content: The protein content for the gluten free Cookies made from buckwheat flour obtained were 15.19.

- Carbohydrate Content: The carbohydrate estimation was carried out through phenol- sulfuric method, where the glucose was used as a standard. The carbohydrate percentage for the gluten free Cookies made from buckwheat flour obtained were73.27.

Conclusion

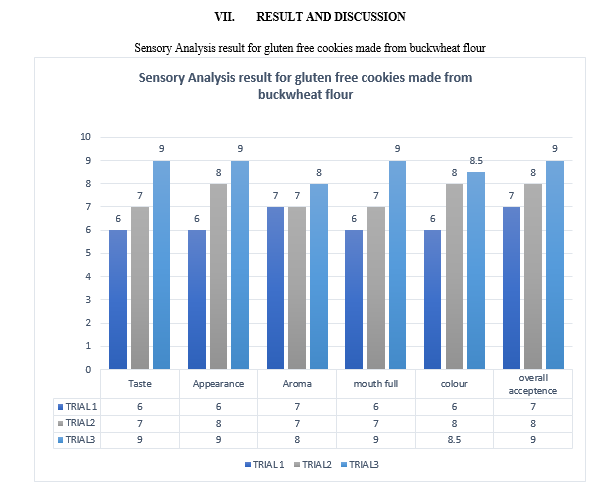

In this study, different combinations of the different types of flour (buckwheat, corn, and rice) were used, and the effect of the flour type on cookie quality was evaluated. In this paper we concluded the physical and chemical properties of buckwheat, corn and rice flour, physical properties of cookies, proximate composition of cookies, sensory analysis of cookies and textural analysis of cookies. The objective to make gluten free cookies is done by using ingredients which are healthy to eat and provide all required nutrition. The incorporation of different levels of buckwheat flour as well as other flour in cookies significantly affected the chemical composition of the developed cookies in positive ways. There was significant increase in ash, moisture, carbohydrate, fiber, and peroxide content. These cookies would be useful for children and families of all economic standings, as a wholesome and inexpensive snack food which is the best Way to incorporate fiber in a diet

References

[1] AACC (1984). Approved Methods of Analysis. St. Paul, MN: The American Association of Cereal Chemists. [2] AACC (1999). Approved Methods of Analysis. (AACC 10-54). St. Paul,MN: The American Association of Cereal Chemists (10th ed, March 2000). [3] AOAC (2002). Oil in Cereal Adjuncts. Gaithersburg, MD, Association of Analytical Communities Official Method 945.16 (Petroleum EtherExtraction Method First action 1945). [4] Atalay MH, Bilgic¸ li N, Elgu¨n A and Demir MK. (2013). Effects of buckwheat (Fagopyrum esculentum Moench) milling products, transglutaminase and sodium stearoyl2-lactylate on bread properties.Journal of Food Processing and Preservation 37: 1–9. [5] Baljeet SY, Ritika BY and Roshan LY. (2010). Studies on functional properties and incorporation of buckwheat flour for biscuit making. International Food Research Journal 17: 1067–1076. [6] Beck M, Jekle M, Selmair PL, Koehler P and Becker T. (2011). Rheological properties and baking performance of rye dough as affected by transglutaminase. Journal of Cereal Science 54: 29–36. [7] Bonafaccia G, Marocchini M and Kreft I. (2003). Composition and technological properties of the flour and bran from common and tartary buckwheat. Food Chemistry 80: 9–15. [8] Catassi C and Fasano A. (2008). Celiac disease. In: Arendt EK and DelBello F (eds) Gluten-Free Cereal Products and Beverages. USA:Academic Press, pp. 1–27. [9] Clerici MTPS, Airoldi C and El-Dash AA. (2009). Production of acidic extruded rice flour and its influence on the qualities of gluten-freebread. LWT- Food Science and Technology 42: 618–623. [10] Dileep AO, Shamasundar BA, Binsi PK and Howell NK. (2010). Composition and quality of rice flour-fish mince based extruded

Copyright

Copyright © 2024 Monika Vijay Chunchawar, Jayanand Morey , Sana Israil Sheikh, Chaitanya Awale, Ajay Durge, Prashant Watkar, Lilesh Pustode. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET62220

Publish Date : 2024-05-16

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online